Staying ahead of competitors

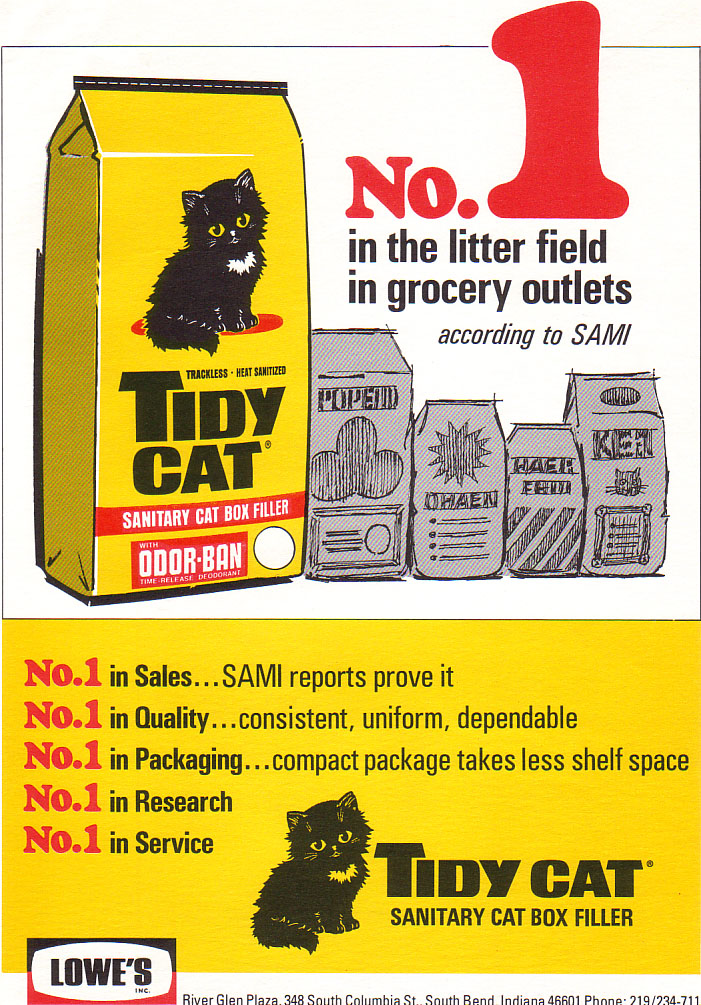

Packaging innovations, creative ad campaigns, and new product lines kept Lowe’s Inc. in the forefront of the pet product industry. In addition to its Kitty Litter and Tidy Cat brands, Lowe’s Inc. began manufacturing private-label cat-box-filler.

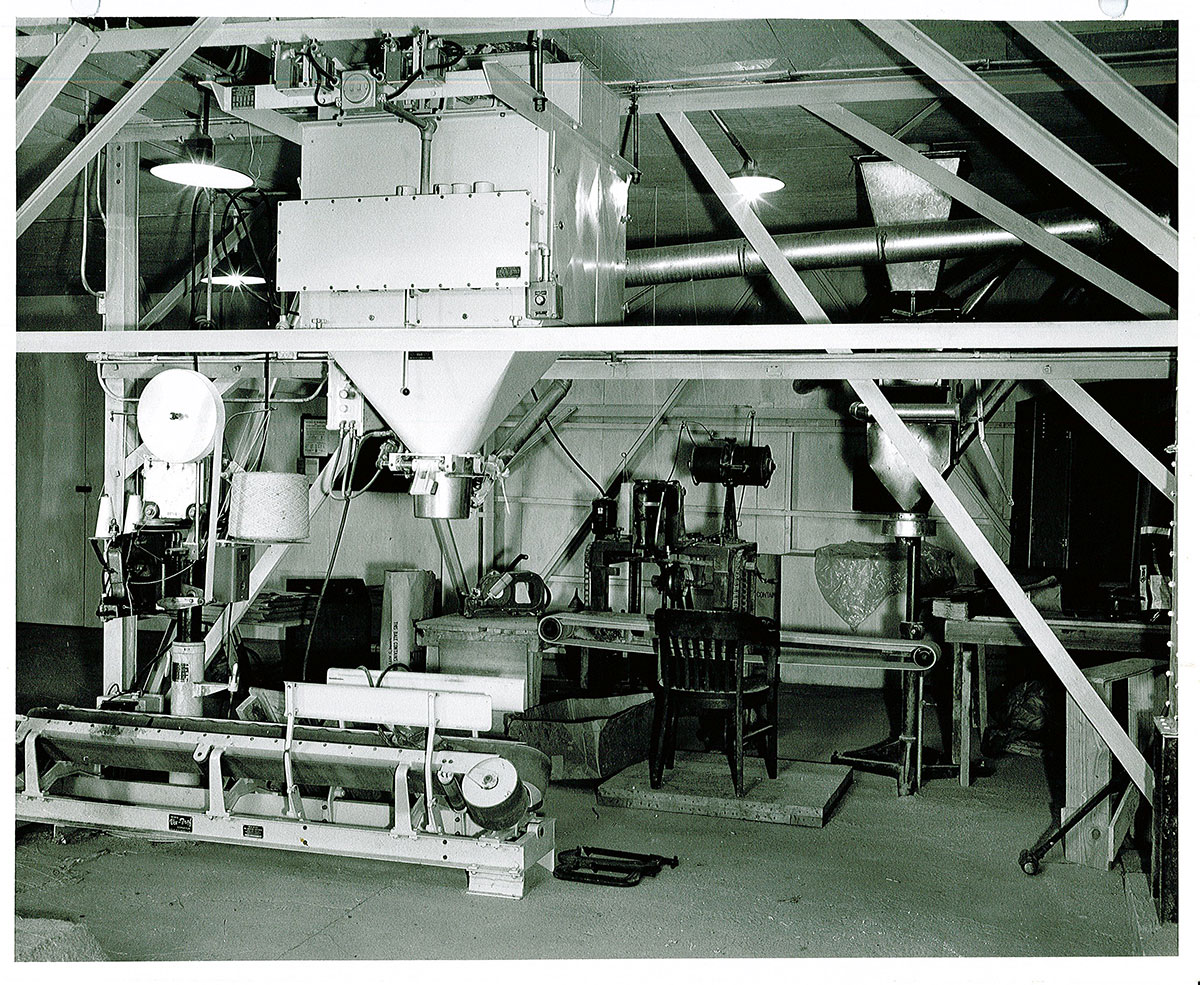

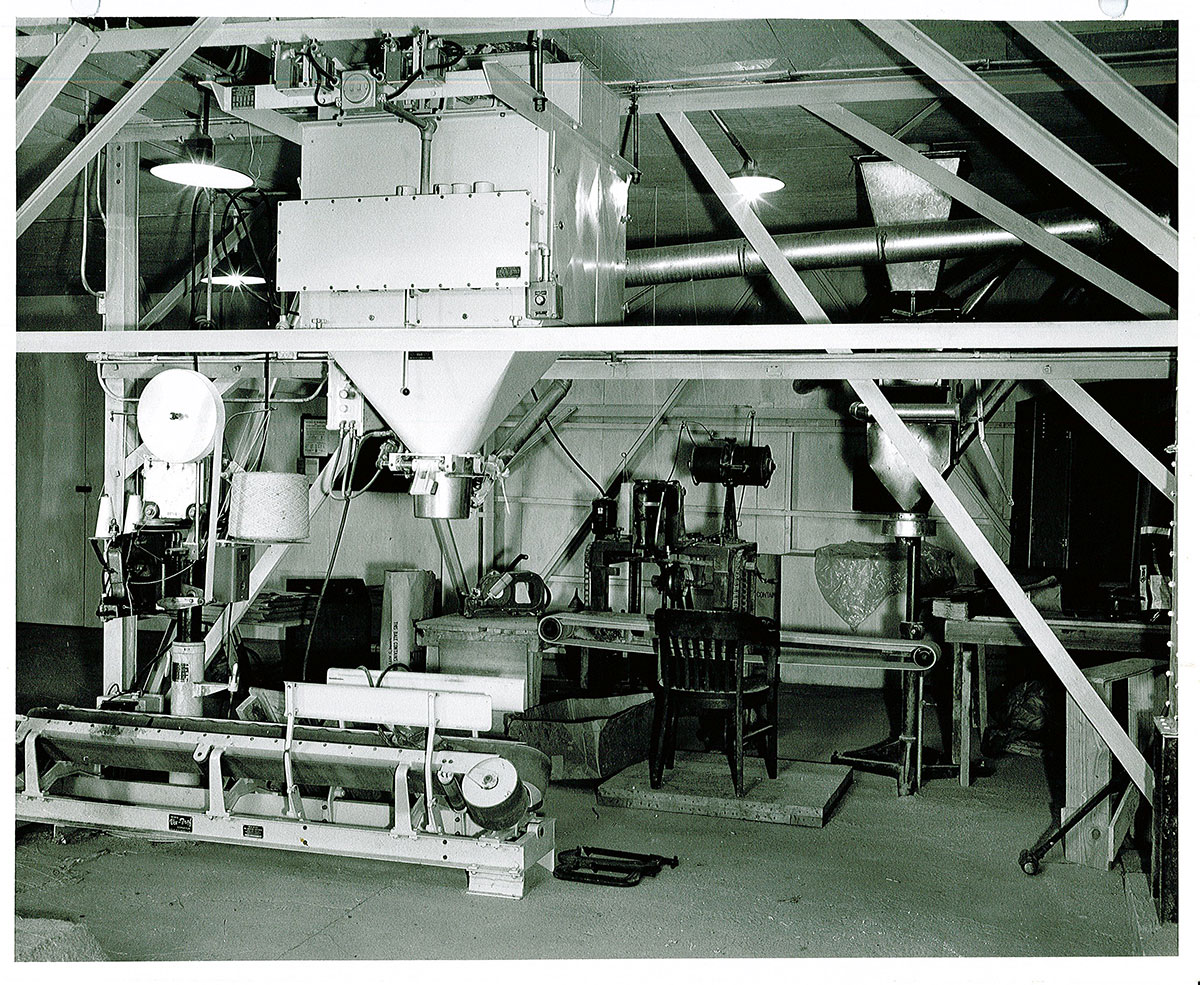

On the operations side, Lowe’s manufacturing facilities grew in size and capacity. The plants also became well known as models of efficiency, which helped the company maintain quality and cost-effectiveness as aggressive “me too” cat-box-fillers began to flood the market.

Expansion highlights included:

- Purchasing a longtime supplier, the Southern Clay Co. in 1965. Major improvements followed and the company started marketing clay as an oil and grease absorbent and — for the first time — as a carrier for fertilizers and insecticides.

- Eliminating a competitor in 1965 with the acquisition of the Tennessee Absorbent Clay Co. in Paris, TN.

- Developing a 35-acre industrial park in Cassopolis, MI. (begun in 1964, completed in 1965), where Lowe’s built a corporate office and packaging plant and established a quality control division.

- Accumulating 625 acres of farmland near Cassopolis, MI., by 1967. Known as Big Rock Valley Farm, this property was used for research and development of absorbent clay products for agricultural, commercial and domestic applications.

In fact, Lowe’s growth is so great during this decade that it was necessary to implement a computer system in 1968 to manage information of all the company’s divisions.

In 1954 Ed introduced a new brand of cat-box-filler, Tidy Cat®, which was sold exclusively in supermarkets. Kitty Litter was then positioned as a boutique brand for pet stores and veterinarians. Although differentiating a core product through branding is now an accepted marketing practice, it was a novel approach at the time.

To meet growing demand, Ed began to increase manufacturing efficiencies. In 1951 he moved his packaging operation from southwest Michigan to a facility in Paris, TN, to be closer to the Southern Clay Co., which provided raw material to his company. In 1958 Ed purchased a manufacturing facility and mining tract in Olmsted, IL. This was a big milestone that enabled him to engage in vertical integration of mining, process and packaging.