Make the best better

“To the creative entrepreneur, the status quo is not a fixed inevitability. It is a target for change. The creative spirit never lets well enough alone.”

— Ed Lowe

Long before the concept of kaizen was embraced by U.S. companies, Ed Lowe was a practitioner of continuous improvement. And as competitors entered his industry, Ed’s passion for refining products and processes enabled Kitty Litter to maintain the lion’s share of sales.

“Ed never stopped asking ‘why?’ about anything,” says Darlene Lowe. “Why are we doing something this particular way? How can it be done better? He never stopped looking for a way to improve every aspect of his business and personal life.”

Ed initially envisioned that Edward Lowe Industries (ELI) “would go on forever.” Yet in later years, this desire shifted into a greater legacy: to support entrepreneurs facing the same challenges he had experienced. As an entrepreneur, Ed strongly identified with the mountain men who pioneered the American West. “I realized I couldn’t perpetuate myself, but what about the breed?” Ed wrote. “What can my life do to help perpetuate the breed called ‘entrepreneur’? How can I help him and her along, make it easier to be a success, to gain strength and recognition?”

Complex personality

“Ed was one of the biggest champions of the consumer,” recalls Tom Kuczmarksi, a marketing consultant and friend. “He wanted to make sure that all of his products were the best quality — from the ease of opening the package to making more healthful products.”

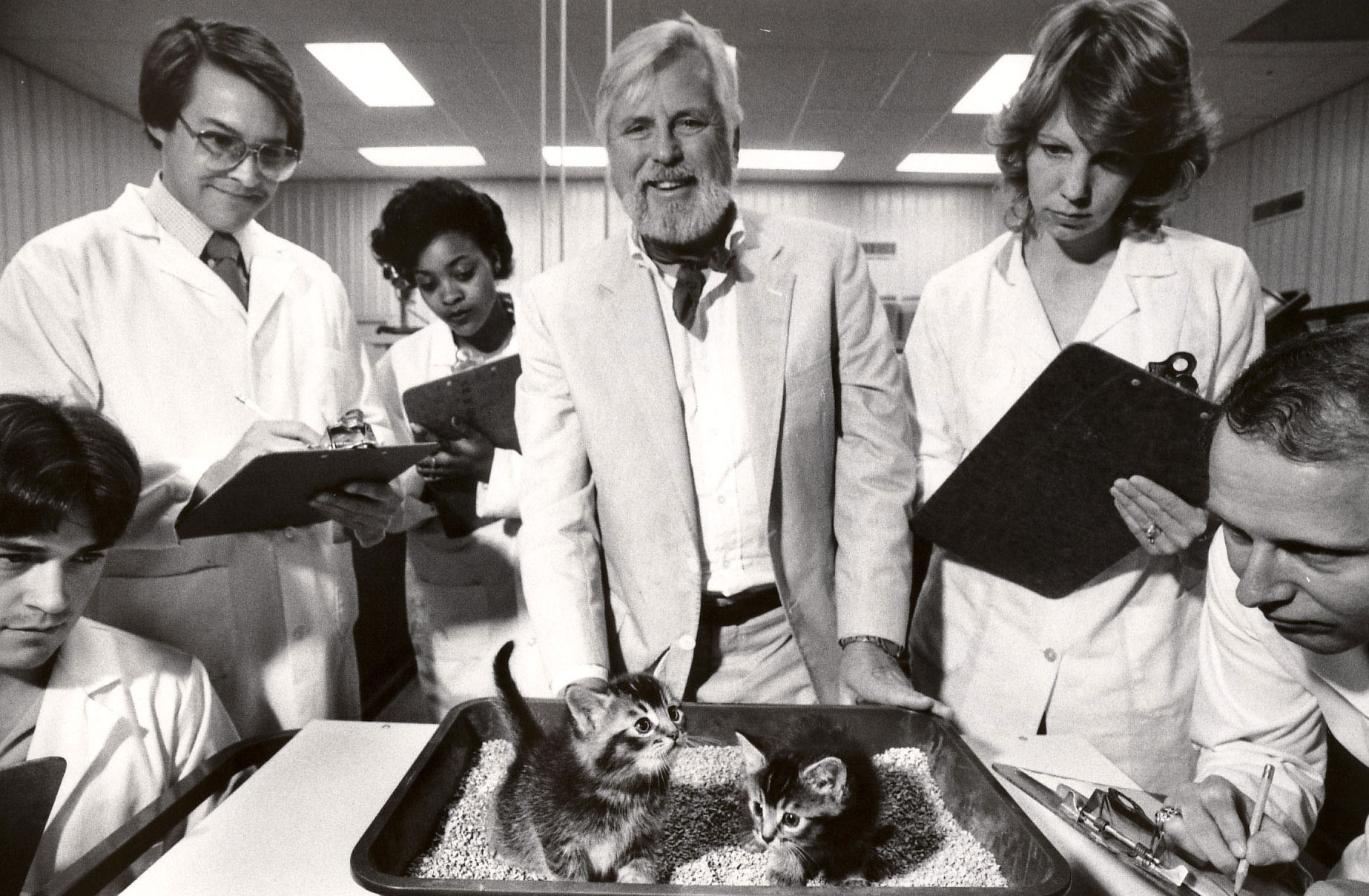

With that in mind, Ed established a dedicated R&D center in Cassopolis, Michigan. Known as the All-American Cattery, more than 120 cats were “on staff” at the center to assist scientists with product development.

Another example of his quest to “make the best better,” Ed developed a “Green Hat” inspection program to ensure his plants were models of safety and efficiency. Wearing green hard hats and white lab coats, a team of inspectors would visit facilities at unannounced intervals and look for potential problems related to safety, maintenance and housekeeping. The program saved ELI a tremendous amount of money in insurance premiums and lost time from accidents. It also produced ideas for improving plant efficiencies, streamlining general procedures and reducing costs.